Products

- Resin Bond Diamond Wheels (19)

- 1A1 Diamond Wheels (9)

- CBN Sharpening Wheel (14)

- Centerless Grinding Wheels (4)

- 1A1R Diamond Wheels (5)

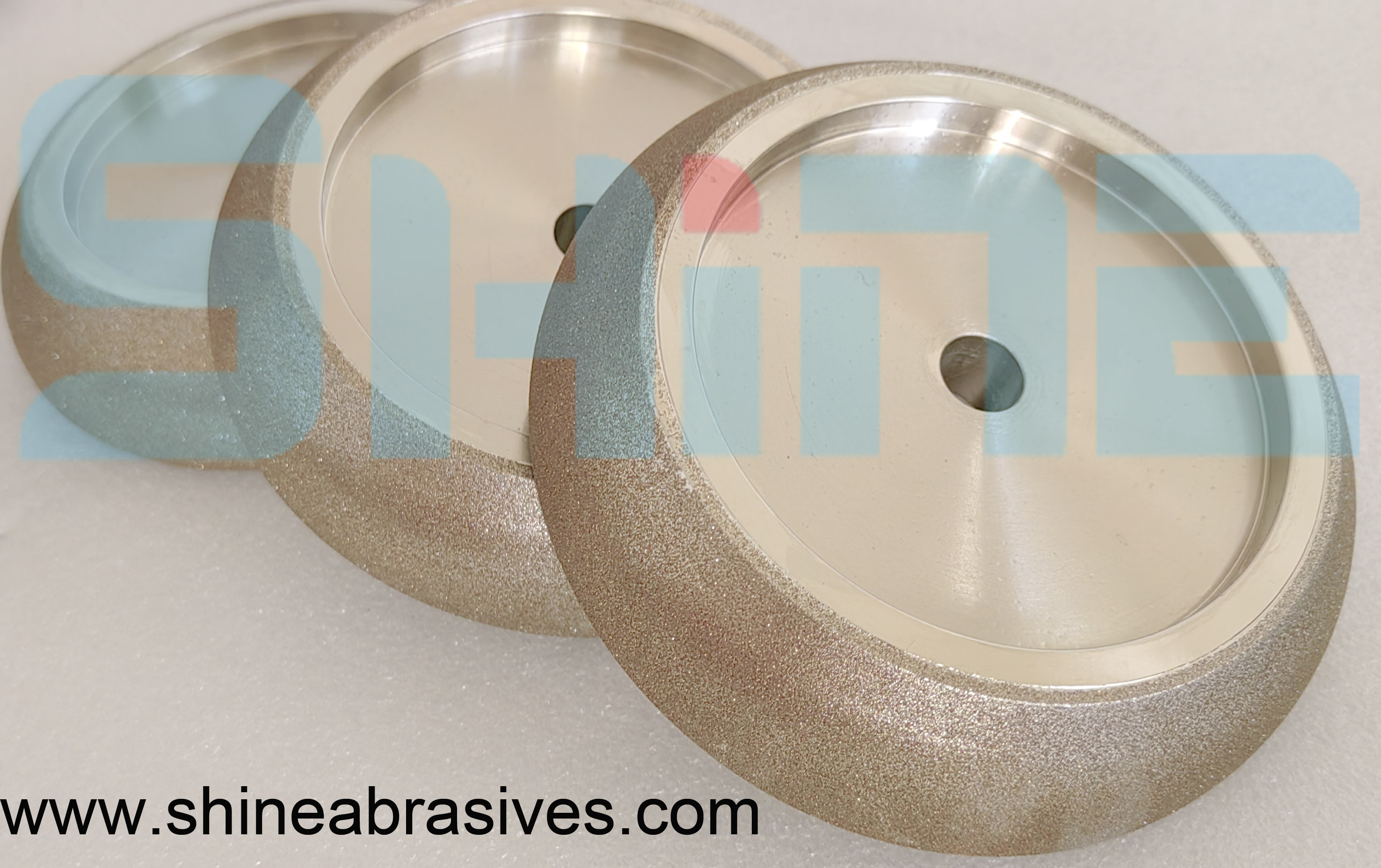

- Electroplated Diamond Wheels (7)

- Electroplated Diamond Tools (7)

- Metal Bond Grinding Wheels (14)

- PCBN Tools (8)

- CNC Grinding Wheels (4)

- Vitrified Bond Wheels (7)

- Diamond Dressing Tools (7)

Contact Us

Tel:+86371-67129055 Mr Li: 15003895611

Fax:+86371-67129055

Email:shineabrasives@vip.163.com

News

Preparation of nanodiamond films

Diamond films generally have a polycrystalline structure. Due to the large surface energy, high surface roughness is produced. This is because the grain size in the diamond film is relatively large. Generally, the average grain size ranges from 1 μm to tens of microns. This will seriously affect the optical and electronic applications of the diamond film. academic applications. In order to overcome this shortcoming, the grain size of the diamond film must be reduced. Although mechanical polishing can reduce the surface roughness, the diamond film is very hard and difficult to polish. Therefore, preparing nanoscale diamond films will become a very effective way.

Conditions for realizing nano-diamond film deposition: First, there must be a very high nucleation density. If the grain size of the diamond film is less than 100 nm, its grain density is about 10¹⁰/cm², so the nucleation density of the diamond film is at least not less than 10¹⁰/cm². In fact, to truly realize the deposition of nanodiamond films, the nucleation density of diamond should be above 10¹⁰/cm². Secondly, a very high secondary nucleation rate is required to inhibit the growth of diamond grains to obtain nanoscale diamond films. If there is no secondary nucleation during the growth of diamond, as the crystal nucleus grows, it will become a micron diamond film (MCD) after a certain period of time; when the nucleation density is very high, the grain size will be smaller than 100 nm nanodiamond film (NCD); when there is a considerable amount of secondary nucleation rate during the growth of the film, the growth process of the film is accompanied by the growth of small crystals and the secondary formation of new crystals on the growing crystal planes. The crystal will become an ultra-nano diamond film (UNCD) with a grain size of 3~5 nm. However, most literature does not distinguish between NCD and UNCD. Since excess H preferentially etches the sp² phase during the MCD growth process, thereby stabilizing the diamond phase and inhibiting secondary nucleation, it is possible to allow the presence of some sp² carbon on the growing crystal plane by reducing the proportion of ammonia to produce New nucleation sites. Domestic and foreign scholars often use different pretreatments on the substrate, add negative bias, and adjust deposition process parameters (gas composition, temperature, pressure), or use a combination of methods to increase the nucleation density or improve the secondary density. nucleation rate to achieve the purpose of preparing nanodiamond films.