Products

- Resin Bond Diamond Wheels (19)

- 1A1 Diamond Wheels (9)

- CBN Sharpening Wheel (18)

- Centerless Grinding Wheels (4)

- 1A1R Diamond Wheels (5)

- Electroplated Diamond Wheels (6)

- Electroplated Diamond Tools (6)

- Metal Bond Grinding Wheels (14)

- PCBN Tools (8)

- CNC Grinding Wheels (4)

- Vitrified Bond Wheels (7)

- Diamond Dressing Tools (7)

Contact Us

Tel:+86371-67129055 Mr Li: 15003895611

Fax:+86371-67129055

Email:shineabrasives@vip.163.com

Metal Bond Grinding Wheels

14F1 metal bond diamond wheel

Shine Abrasives Metal Bond Diamond Wheels For Tungsten Carbide Roll

grinding and specific shape forming.

Metal bonded wheels use metallic powders as a binder. It is excellent in form maintenance and wear resistance. Mainly based on Cu and Sn.

Metal bonded wheels can be designed in complicated profile

for high precision grinding. Also, it shows good performance in grinding

steel rolls for rolling and other processes.

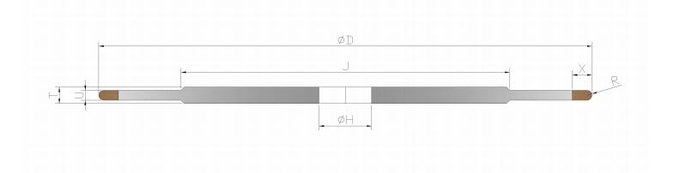

The drawing of Shine Abrasives Metal Bond Diamond Wheels For Tungsten Carbide Roll Shape Grinding.

Main sizes form of Shine Abrasives Metal Bond Diamond Wheels For Tungsten Carbide Roll Shape Grinding

| Abrasive Material:Diamond | Bond Type:Metal |

| CBN Grit:D126 | Wheel Diameter: 8inch 200mm |

| Wheel Bore:76mm | Wheel Weight:4.0kgs/PC |

| Wheel Thickness:20mm | Concentrate: 125% |

Other standard sizes also are available as requested.

Features of Shine Abrasives Metal Bond Diamond Wheels For Tungsten Carbide Roll Shape Grinding

Highest wear resistance and profile retention

Thermally resistant

Many sizes and Diamond grits are available.

Long time wheel working life

Question.

What's metal bond diamond grinding wheel?

Metal bond diamond grinding wheel mostly uses bronze and other metals as the bond,

and is manufactured by high temperature sintering method.

metal bond diamond wheels have features:high bonding strength, good form-ability, high temperature resistance,

good thermal conductivity and wear resistance, long service life, and can withstand large loads.

Application pictures for reference.