Products

- Resin Bond Diamond Wheels (19)

- 1A1 Diamond Wheels (9)

- CBN Sharpening Wheel (18)

- Centerless Grinding Wheels (4)

- 1A1R Diamond Wheels (5)

- Electroplated Diamond Wheels (6)

- Electroplated Diamond Tools (6)

- Metal Bond Grinding Wheels (14)

- PCBN Tools (8)

- CNC Grinding Wheels (4)

- Vitrified Bond Wheels (7)

- Diamond Dressing Tools (7)

Contact Us

Tel:+86371-67129055 Mr Li: 15003895611

Fax:+86371-67129055

Email:shineabrasives@vip.163.com

1A1 Diamond Wheels

1A1 for Cemented Carbide Cylindrical Grinding

1A1 Diamond Wheels 14'' For Cemented Carbide Cylindrical Grinding

Shine Abrasives Resin bond 1A1 Diamond Wheels 14'' For Cemented Carbide Cylindrical Grinding

1A1 Type Straight Diamond wheels mainly used for below materials grinding.

Hard materials of tugsten carbide and ceramics for wear-resistant coatings.

Tungsten carbide materials or tools.

Nickel- or titanium-based super alloys

ceramics

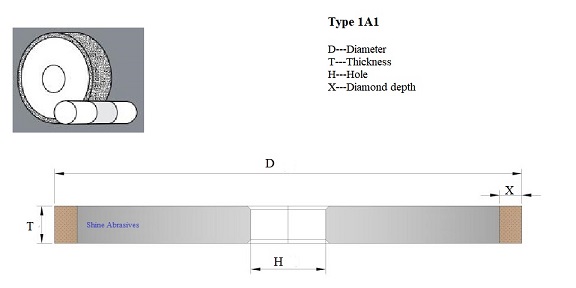

The drawing of Shine Abrasives 1A1 Diamond Wheels 14'' For Cemented Carbide Cylindrical Grinding

Main sizes form of Shine Abrasives 1A1 Diamond Wheels 14'' For Cemented Carbide Cylindrical Grinding

| Abrasive Material:Diamond | Bond Type:Resin |

| CBN Grit:D126 | Wheel Diameter:350mm |

| Wheel Bore:127mm | Wheel Weight:9kgs/PC |

| Wheel Body Material:Aluminum | Diamond Ring Width:10mm |

| Wheel Thickness:25mm | Concentrate: 125% |

Other standard sizes also are available as requested.

Question:

What's the advantages of Resin bond diamond grinding wheels?

High grinding efficiency and grinding wheel slow consumption.

Good self-sharpening, low heat value produce when grinding,

Reducing the phenomenon of work burns the workpieces during grinding

The grinding wheel has a certain elasticity, which is conducive to improving the roughness of the workpiece surface.

It is mainly used for fine grinding, semi-fine grinding, knife grinding, polishing and other processes.

Application picture for reference.