Products

- Resin Bond Diamond Wheels (19)

- 1A1 Diamond Wheels (9)

- CBN Sharpening Wheel (18)

- Centerless Grinding Wheels (4)

- 1A1R Diamond Wheels (5)

- Electroplated Diamond Wheels (6)

- Electroplated Diamond Tools (6)

- Metal Bond Grinding Wheels (14)

- PCBN Tools (8)

- CNC Grinding Wheels (4)

- Vitrified Bond Wheels (7)

- Diamond Dressing Tools (7)

Contact Us

Tel:+86371-67129055 Mr Li: 15003895611

Fax:+86371-67129055

Email:shineabrasives@vip.163.com

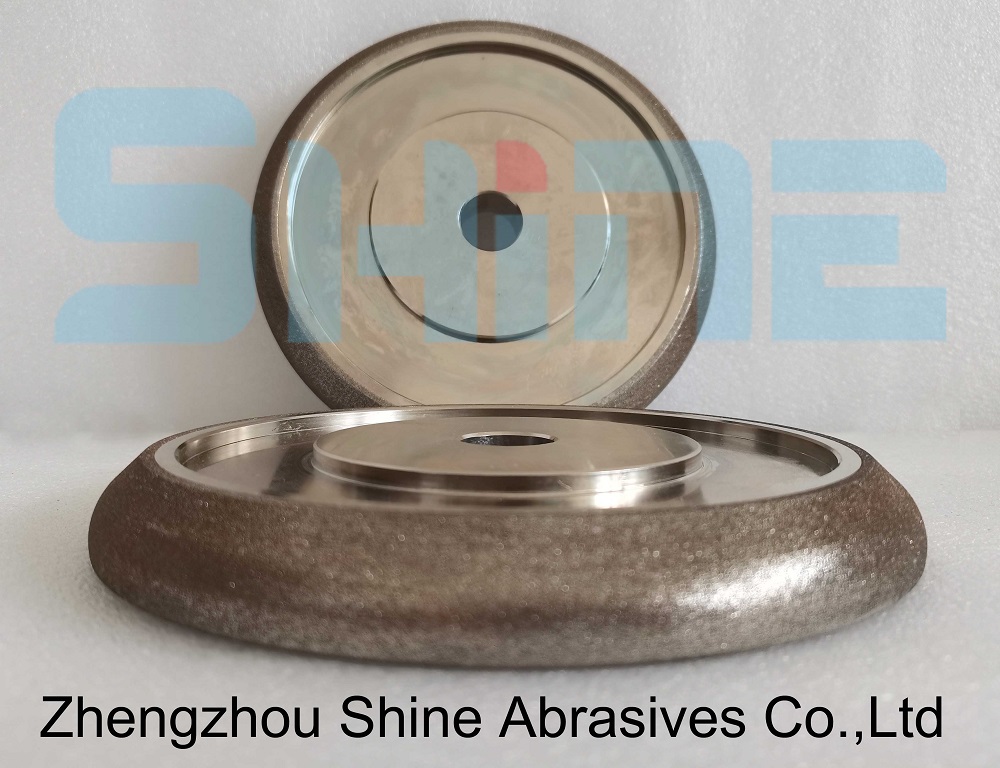

CBN Sharpening Wheel

203mm CBN Sharpening Wheel For 7/8 Inch Tooth Spac

203mm CBN Sharpening Wheel For 7/8 Inch Tooth Spacing Band Saw Blades

Shine Abrasives 8 inch 203mm CBN wheels for Wood Mizer 10/30 profile band saw blades sharpening

10/30 profile is the very popular band saw blades. 10/30 is usual also called 10° profile.

The saw tooth spacing is 7/8 inch =22.22mm. the wheel bore sizes are usual 25.4mm or 32mm

8" (203mm) diameter CBN grinding wheel for sharpening Wood-Mizer SilverTip, DoubleHard,

and Bi-Metal bandsaw blades with 7/8" tooth spacing.

Suitable for Wood-Mizer BMS500 bandsaw blade sharpeners and others grinders using 8" or 203mm diameter wheels.

For band saw blades types in below:

Wood-Mizer SilverTip, Wood-Mizer DoubleHard, Wood-Mizer Bi-Metal,

Timberwolf, Simonds, Kasco, Morse, Lenox, Dakin Flathers/Ripper 37.

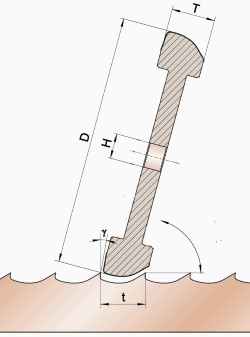

The drawing of Shine Abrasives 203mm CBN Sharpening Wheel For 7/8 Inch Tooth Spacing Band Saw Blades

The size form of Shine Abrasives 203mm CBN Sharpening Wheel For 7/8 Inch Tooth Spacing Band Saw Blades

| Abrasive Material:CBN | Bond Type:Electroplated |

| CBN Grit:100# | Wheel Diameter:8 Inch=203mm |

| Wheel Bore:25.4m or 32mm | Wheel Weight:4.6kgs/PC |

| Wheel Thickness:22.2mm | Body Material: Steel |

Other sizes also are available as requested.

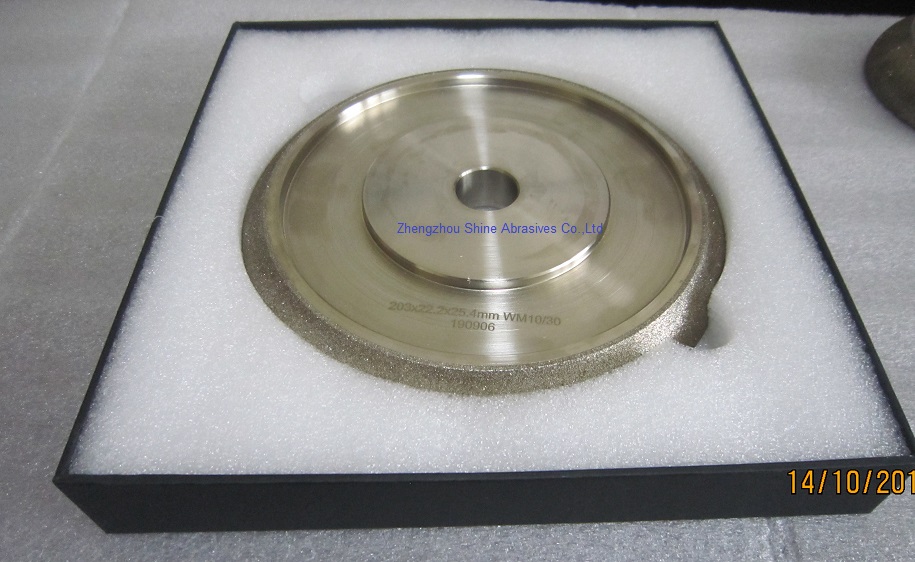

Package of Shine Abrasvies 203mm CBN Sharpening Wheel For 7/8 Inch Tooth Spacing Band Saw Blades

Single wheel in one black color paper box as below picture.

4 PCS Wheels are in one export carton.

Features of Shine Abrasvies 8 Inch CBN Sharpening Wheel For Wood Mizer Sawmill Band Saw Blades

Fast sharpening speed Good finish after grinding or sharpening.

Wheels with Longer life than traditional grinding wheels

Cost-effective No need dressing

Application picture for reference