Products

- Resin Bond Diamond Wheels (19)

- 1A1 Diamond Wheels (9)

- CBN Sharpening Wheel (18)

- Centerless Grinding Wheels (4)

- 1A1R Diamond Wheels (5)

- Electroplated Diamond Wheels (6)

- Electroplated Diamond Tools (6)

- Metal Bond Grinding Wheels (14)

- PCBN Tools (8)

- CNC Grinding Wheels (4)

- Vitrified Bond Wheels (7)

- Diamond Dressing Tools (7)

Contact Us

Tel:+86371-67129055 Mr Li: 15003895611

Fax:+86371-67129055

Email:shineabrasives@vip.163.com

Metal Bond Grinding Wheels

14FF1 metal bond diamond wheel

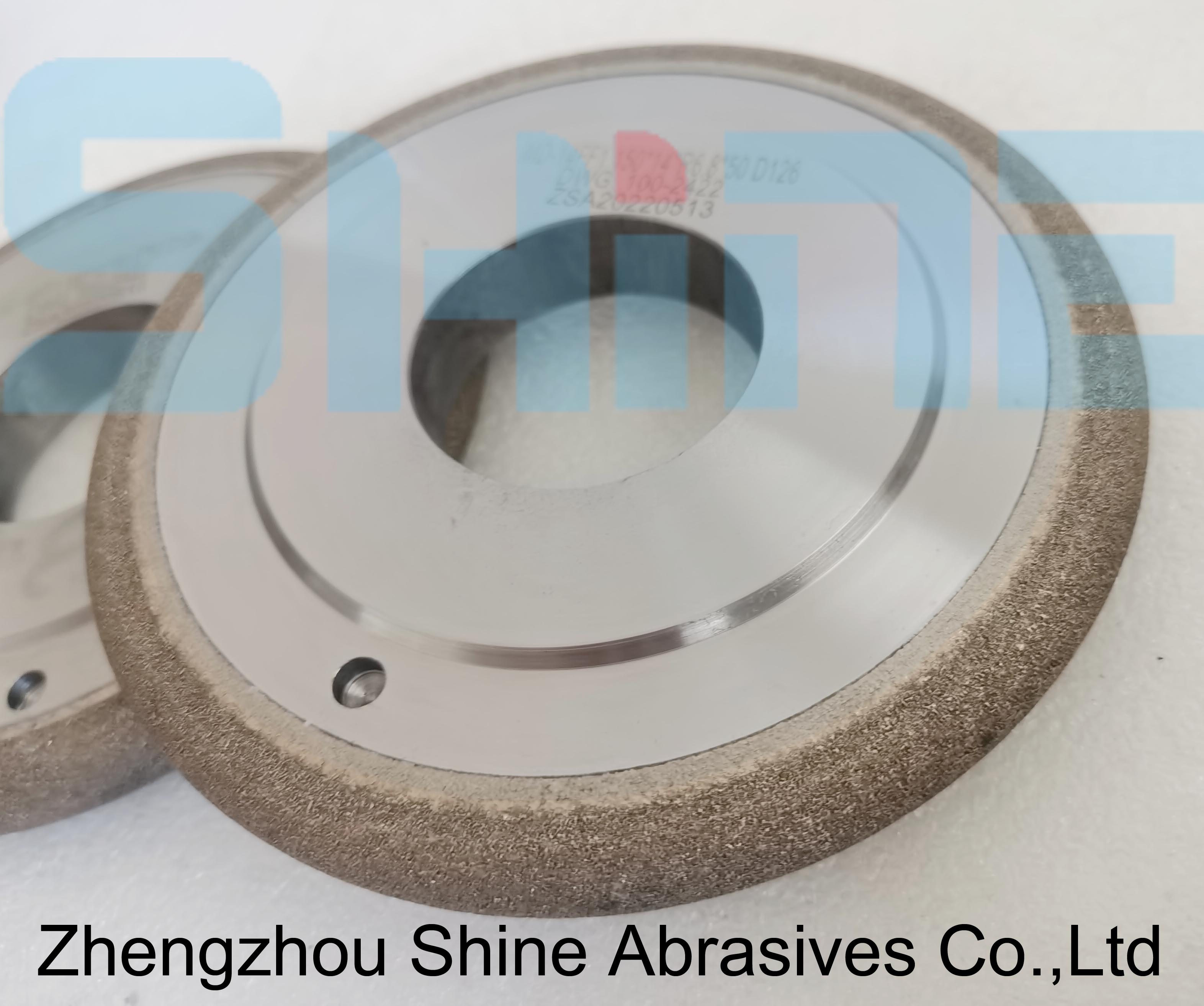

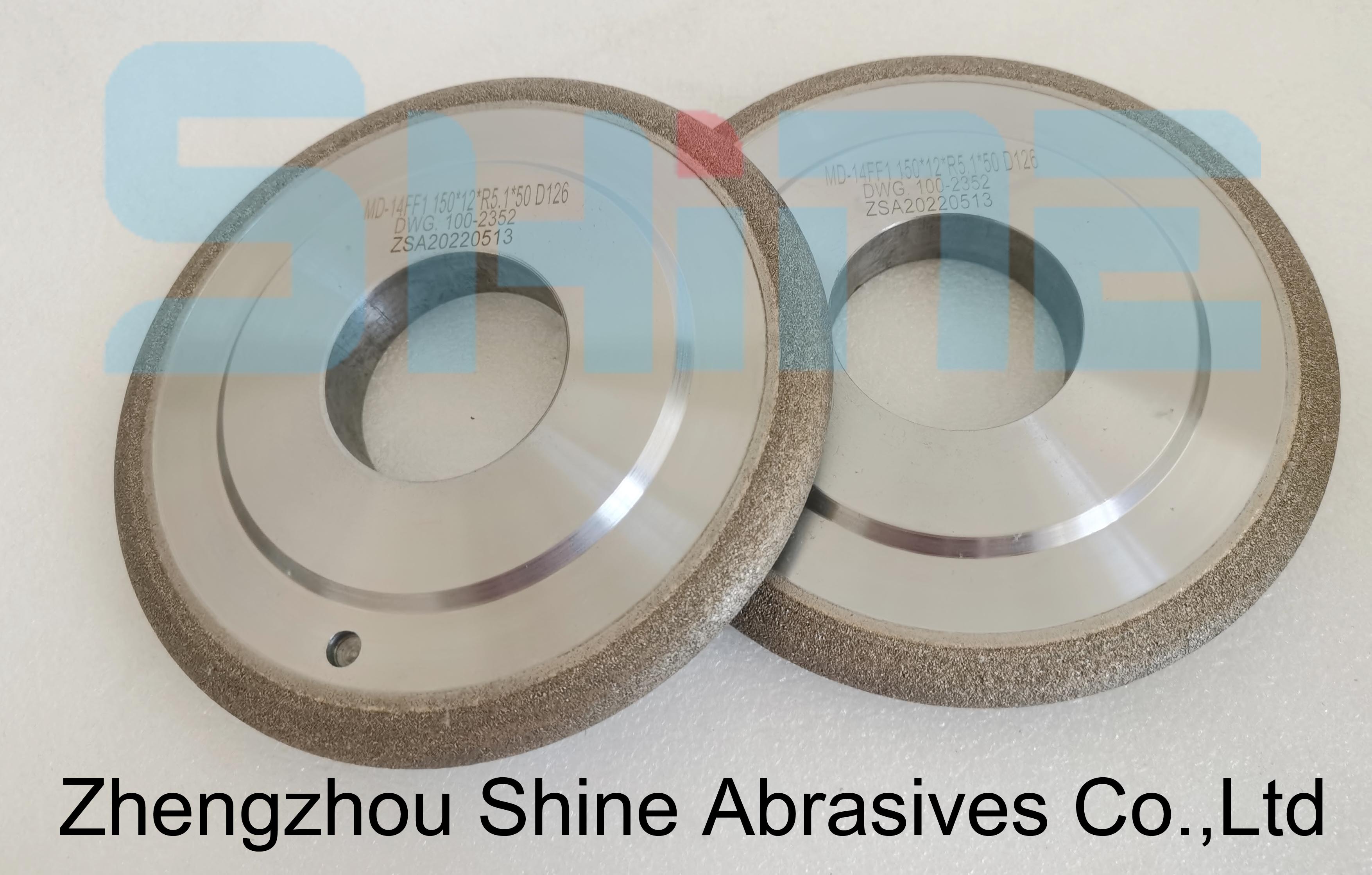

Shine Abrasives Metal Bond Diamond Wheels For Tungsten Carbide Roll Profile Grinding

Shine Abrasives Metal Bond Diamond Wheels For Tungsten Carbide Roll

grinding and specific shape forming.

The drawing of Shine Abrasives Metal Bond Diamond Wheels For Tungsten Carbide Roll Profile Grinding

Main sizes form of Shine Abrasives Metal Bond Diamond Wheels For Tungsten Carbide Roll Profile Grinding

| Abrasive Material:Diamond | Bond Type:Metal |

| CBN Grit:D126 | Wheel Diameter: 6inch 150mm |

| Wheel Bore:76mm | Wheel Weight:2.5kgs/PC |

| Wheel Thickness:22mm | Concentrate: 150% |

Other standard sizes also are available as requested.

Features of Shine Abrasives Metal Bond Diamond Wheels For Tungsten Carbide Roll Shape and profile Grinding

metal bond wheel is binding of materials of metallic powders of copper , tin, iron, cobalt, etc. It has excellent grit retention and wear resistance compared to other wheels.

Metal bond wheels have excellent grit retention and wear resistance compared to resin bond wheels.

Metal bond wheels are divided into the major types bronze-type which is superior in grinding ability. Cobalt type which is superior in wheel life and steel-type which stands in the middle in grinding capability.

Metal bond wheels also can be used for electrolytic grinding and electrical discharge grinding using its electric conductivity

No matter what kind of material you're working with, we have the right bond to meet your needs – whether you need it to cut glass or tougher silicon carbide to cut through titanium alloy.

Utilizing metal bonds results in a product that holds its shape longer than any other bond system during use. By applying CBN or Diamond powders to the metal bond, wheel life and form holding characteristics are enhanced.

Metallic bond grinding wheels perform exceptionally well for extended periods. Metal bonds assure consistent precision and reduce the need for wheel replacement. Metal bonds provide clean cuts and do not require dressing for longer periods of time.

Application pictures for reference.