Products

- Resin Bond Diamond Wheels (19)

- 1A1 Diamond Wheels (9)

- CBN Sharpening Wheel (18)

- Centerless Grinding Wheels (4)

- 1A1R Diamond Wheels (5)

- Electroplated Diamond Wheels (6)

- Electroplated Diamond Tools (6)

- Metal Bond Grinding Wheels (14)

- PCBN Tools (8)

- CNC Grinding Wheels (4)

- Vitrified Bond Wheels (7)

- Diamond Dressing Tools (7)

Contact Us

Tel:+86371-67129055 Mr Li: 15003895611

Fax:+86371-67129055

Email:shineabrasives@vip.163.com

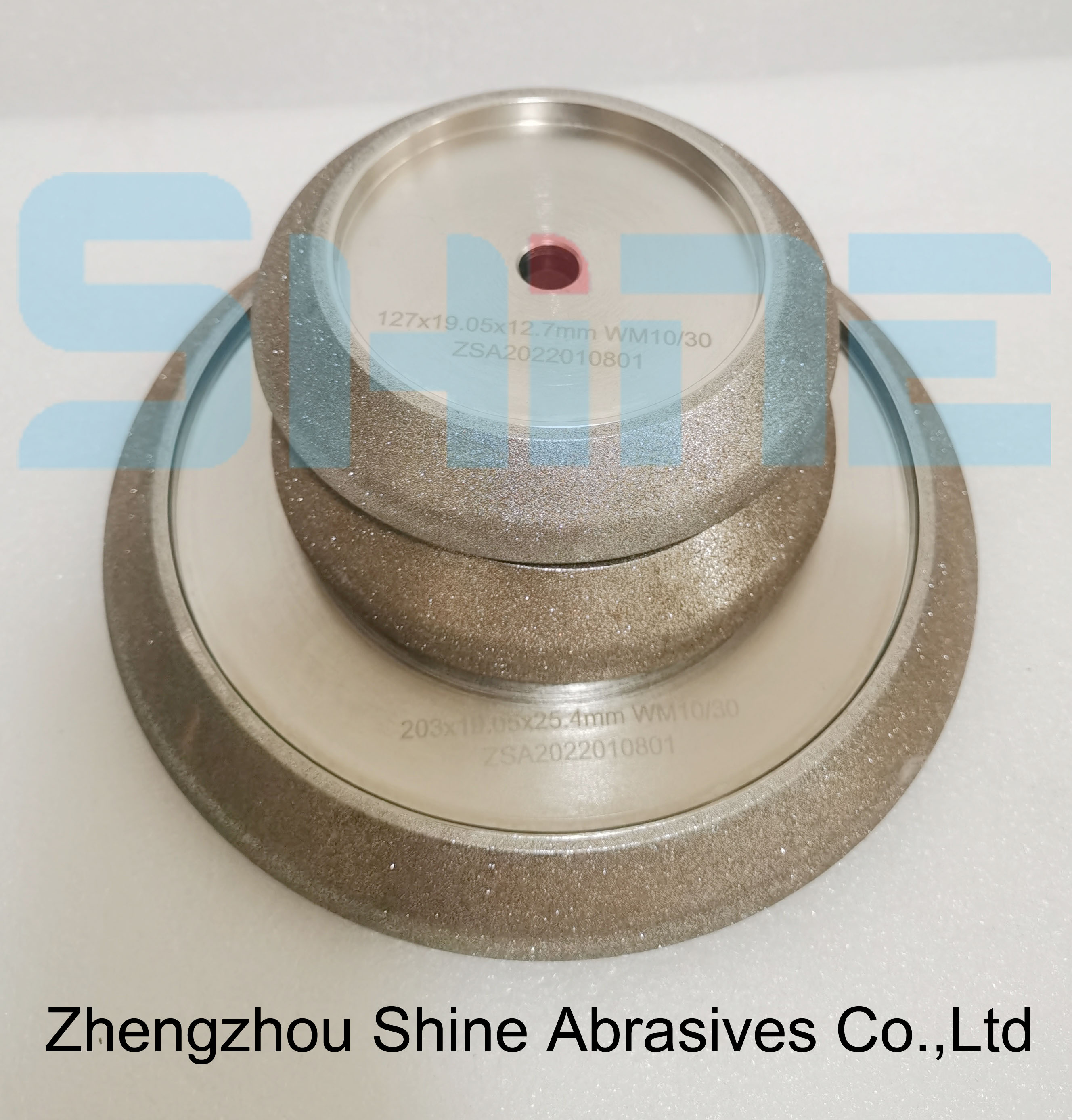

CBN Sharpening Wheel

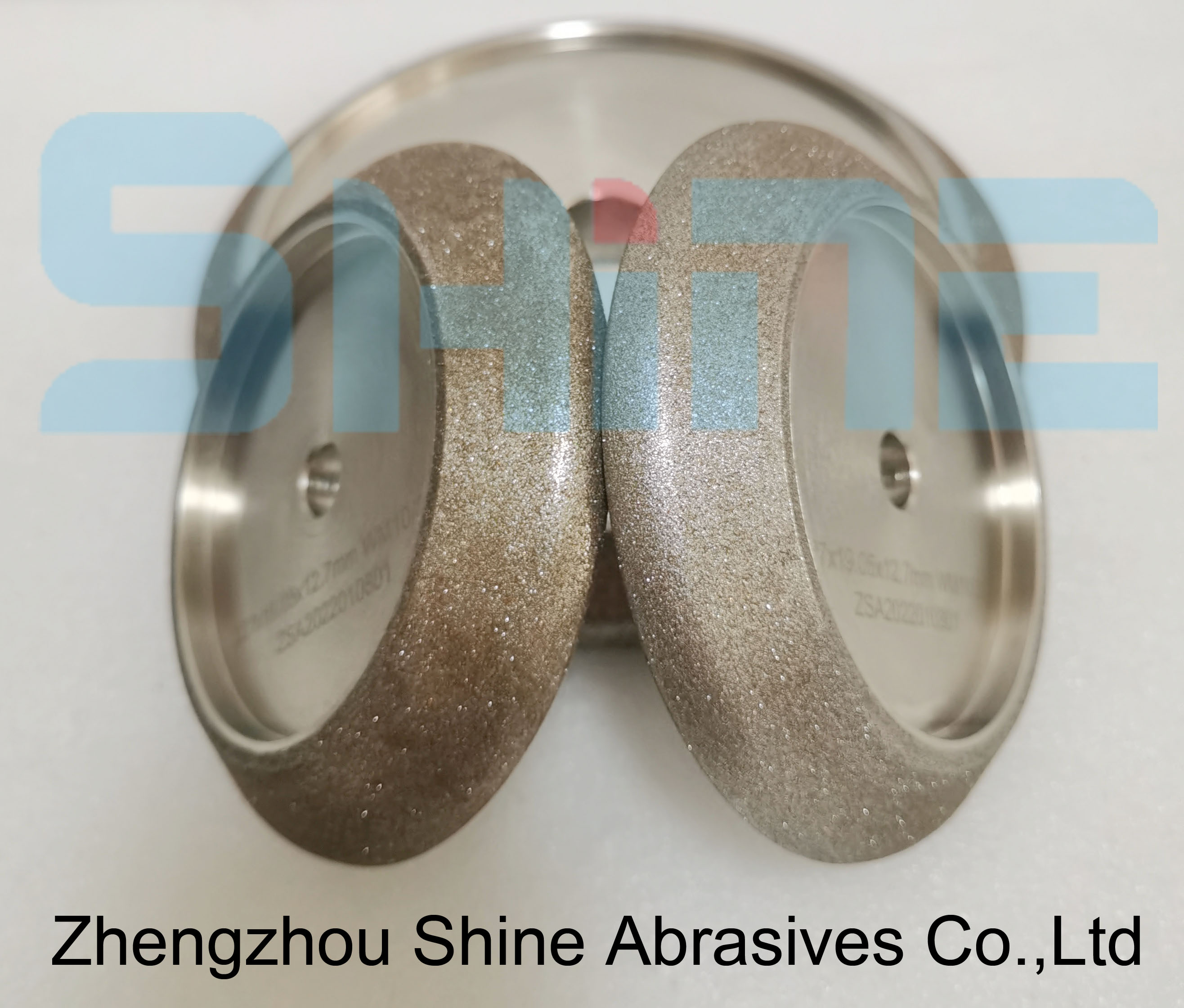

CBN grinding wheels for band saw blades

Electroplated (galvanic)CBN profile grinding wheels are used for sharpening high-alloy bandsaw.

Electroplated Diamond Wheels - Manufactured by Shine Abrasives can be manufactured in a variety of sizes and styles, both standard and custom to your specific forms and are designed primarily for grinding such materials as: Carbide, Ceramic,carbon, graphite, Quartz, lumina, Earth Magnet, Glass, Silicon, Honeycomb Composites, Stone Materials, etc. Braemar's precision Diamond Form Wheels can be manufactured to you exact needs. We can furnish a coupon of the required form with each wheel. We also have the capability of machining the wheel on your adapter eliminating the time necessary for indicating. When you compare the performance, service and price of Shine Abrasives's superabrasive products, you will find that our form wheels give you the value you have been looking for.

CBN grinding wheels are commonly used to process band saws brands, including

Wood-Mizer, Timberwolf, Simonds, Kasco, Morse, Lenox, Dakin Flathers/Ripper 37 and others.

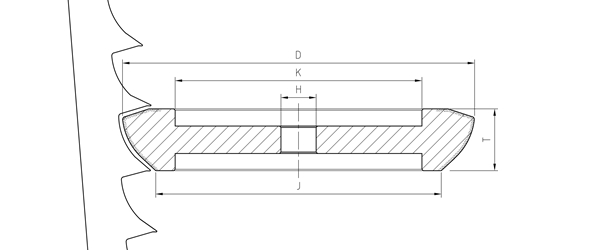

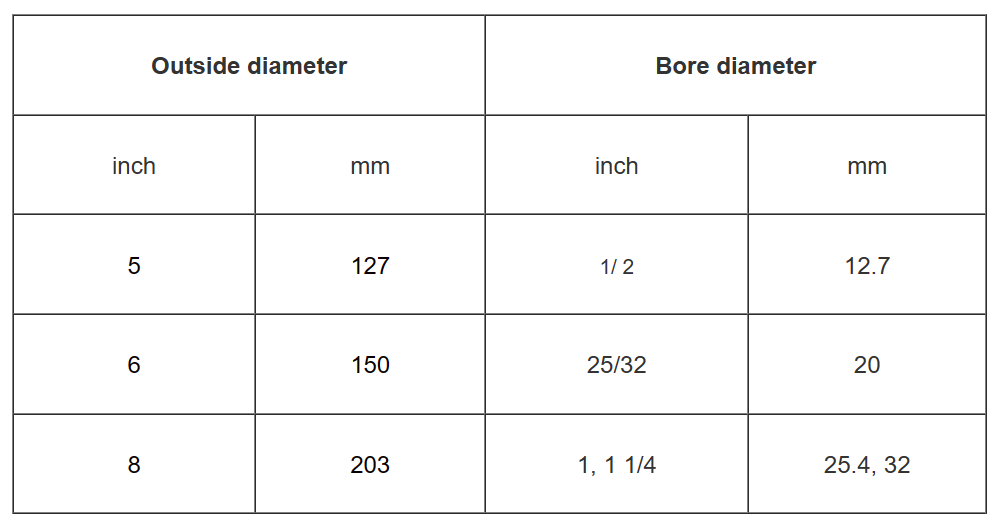

The drawing of CBN grinding wheels (galvanic wheels) for band saw blades

Special size can be produce according to the band saw profile.

Different wheel profiles for all kind of wood and seasons are available

* 10/30 - mostly used universal grinding wheel profile

* 9/29 - perfectly prepares band saws for winter time cutting, or cutting hard Wood

* 13/29 - wheel profile which prepares band saws for soft wood cutting

* 4/32 - wheel profile which can prepare band saws for very frozen and very hard wood cutting

* 7/34 the CBN wheels profile is recommended for hardwood.

No wheel dressing necessary.

No wheel dressing necessary.