Products

- Resin Bond Diamond Wheels (19)

- 1A1 Diamond Wheels (9)

- CBN Sharpening Wheel (18)

- Centerless Grinding Wheels (4)

- 1A1R Diamond Wheels (5)

- Electroplated Diamond Wheels (6)

- Electroplated Diamond Tools (6)

- Metal Bond Grinding Wheels (14)

- PCBN Tools (8)

- CNC Grinding Wheels (4)

- Vitrified Bond Wheels (7)

- Diamond Dressing Tools (7)

Contact Us

Tel:+86371-67129055 Mr Li: 15003895611

Fax:+86371-67129055

Email:shineabrasives@vip.163.com

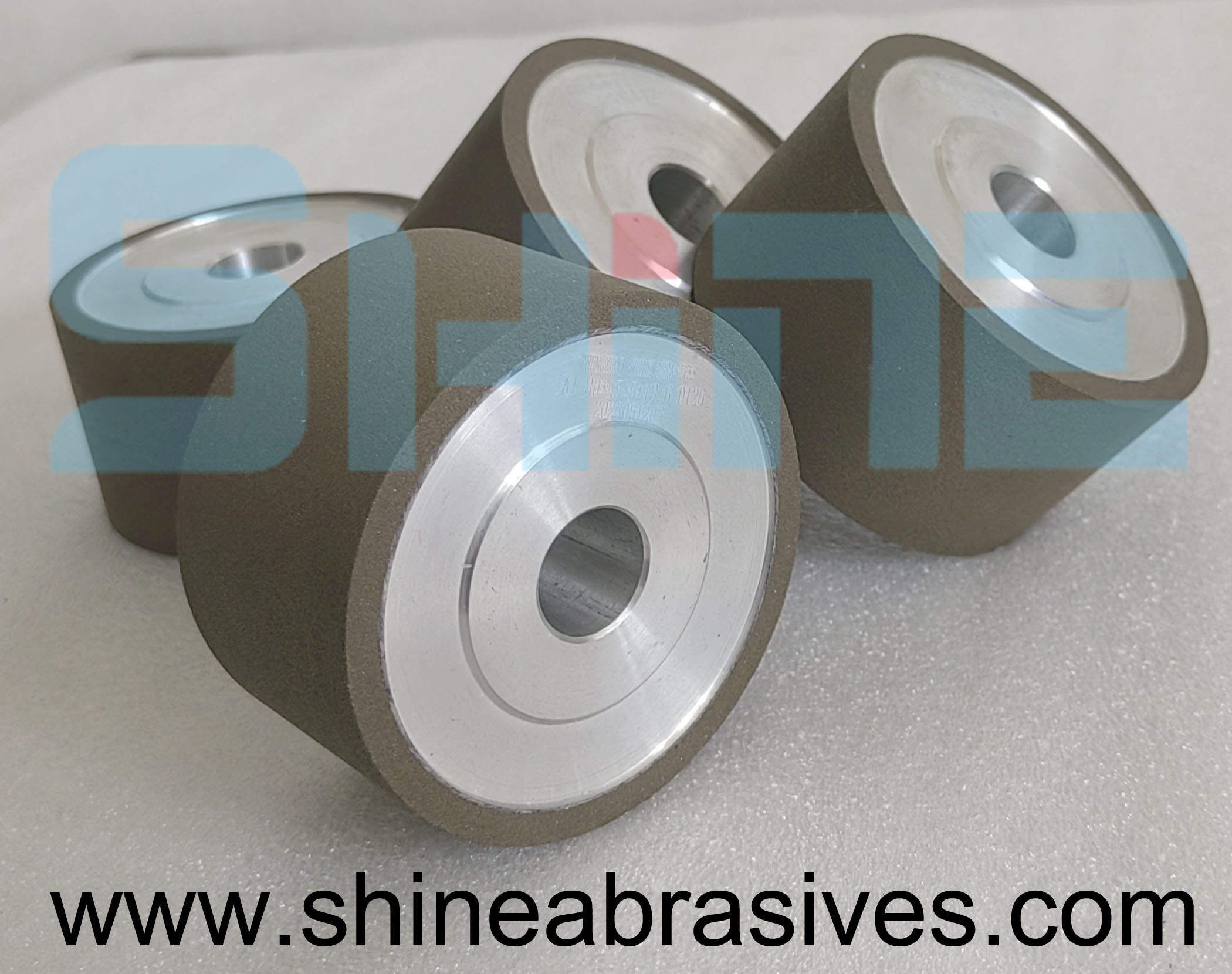

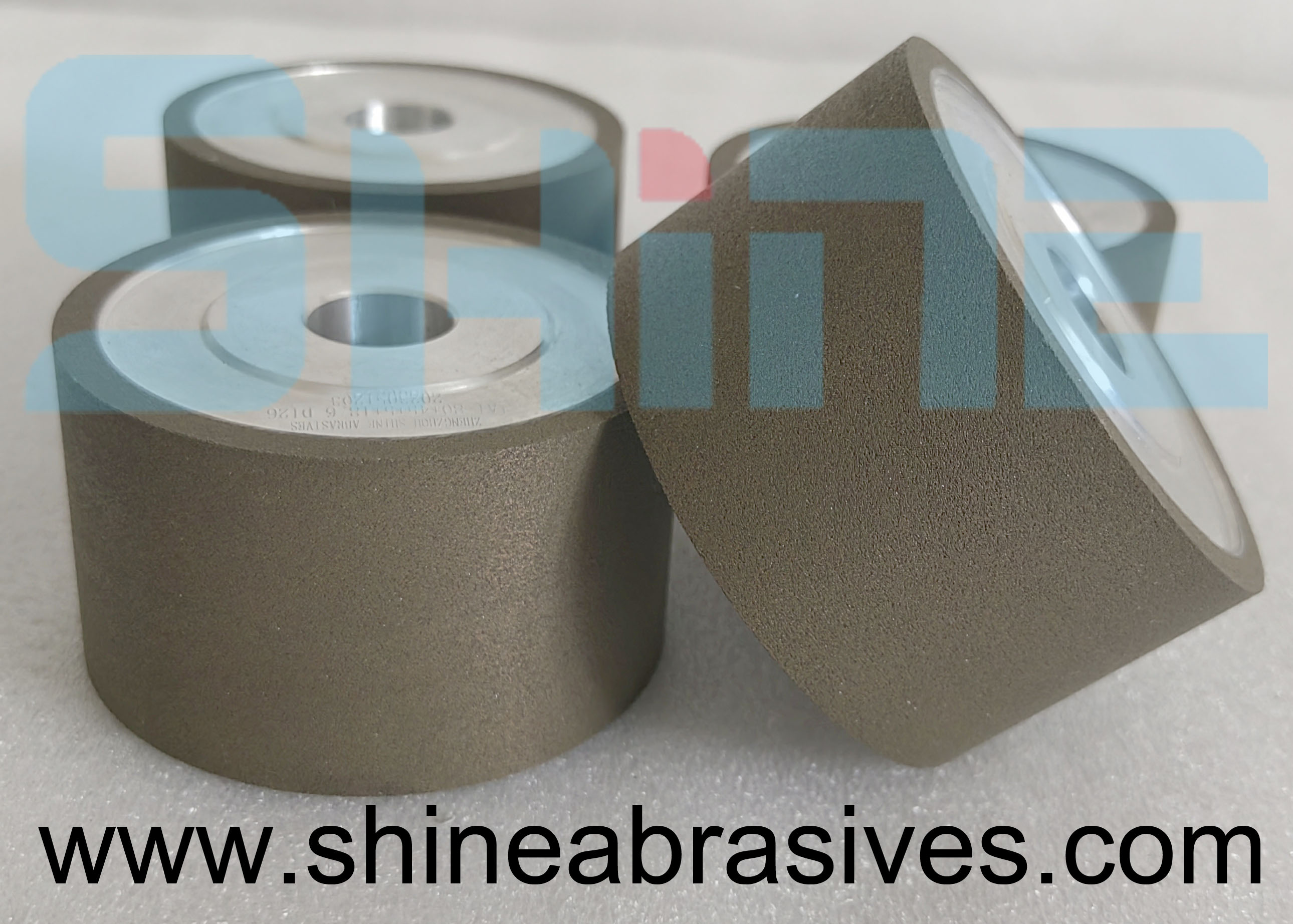

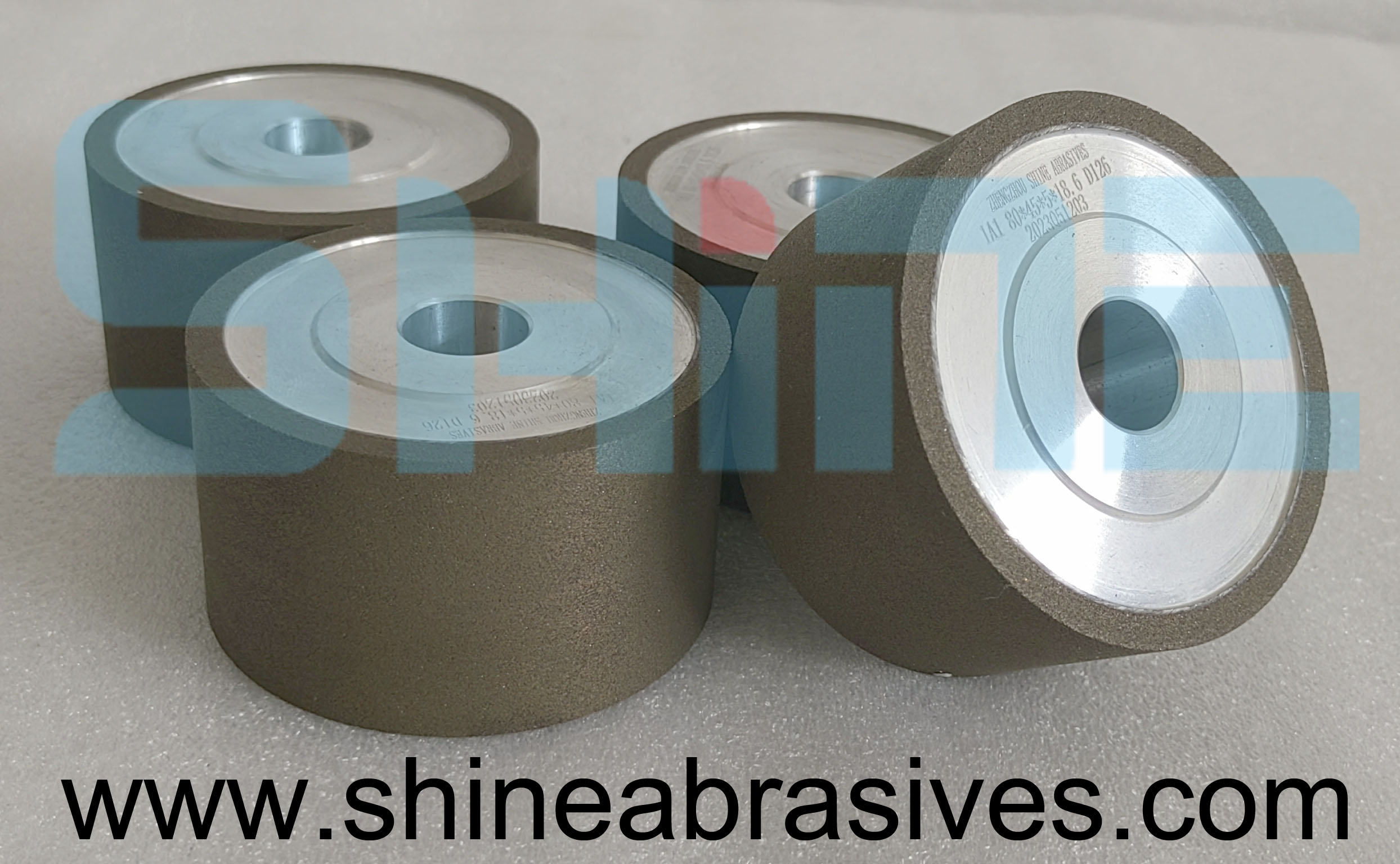

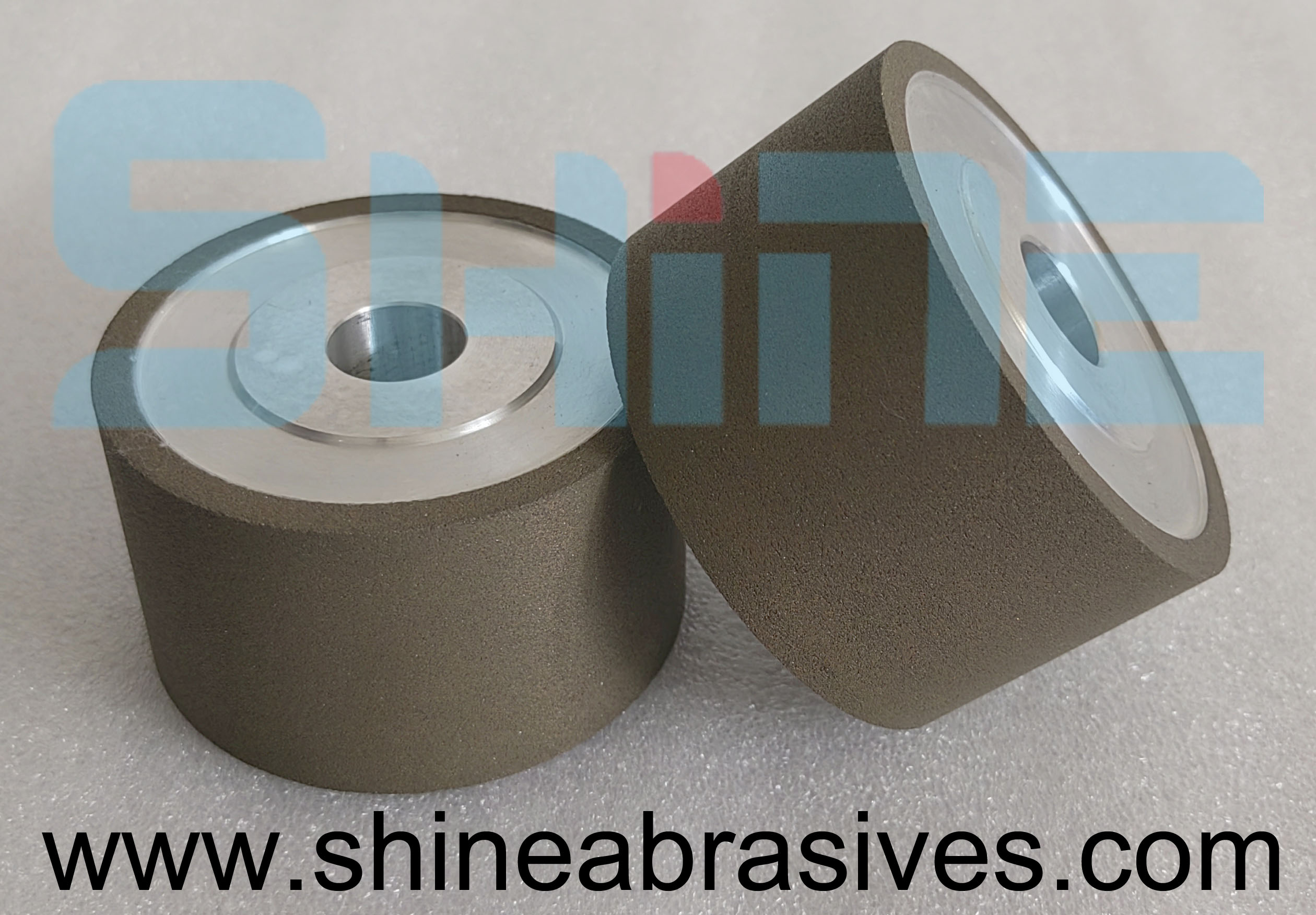

1A1 Diamond Wheels

1A1 Diamond Wheel for Carbide Sharpening Knife

Shine 1A1 Flat Shaped Resin Bond Diamond Wheel for Carbide Sharpening Knife

CBN is a man-made superabrasive that outperforms diamond when used for ferrous (iron-rich) grinding operations. CBN derives its name from its chemical makeup (cubic boron nitride). When working with ferrous (iron-rich) materials, CBN is the superabrasive of choice. CBN is a highly-durable, synthetic abrasive mineral. This type of grinding wheel works best with steel or cast iron application. When coupled with high temperatures, CBN is of an unreactive nature, making it the preferred choice for “heated situations”. Because of this, CBN wheels can be used at high speeds without affecting the life of the wheel.

CBN grinding wheels are used to sharpen, cut, or remove metal from hard surfaces, providing a consistent and even finish. Our CBN wheel can accurately cut metals, glass, and even diamonds. Most notably CBN wheels are used for hard, high-speed steels like woodworking tools, blades, bits, and cutters. When you’re tools become dull over time from use, a CBN wheel will bring them back to life.

Resin bond diamond wheels are primarily used in industries that work with carbide cutting tools, ceramics, glass, quartz, thermal spray, and specialty materials. These tools can be utilized for numerous grinding applications, including:

● Surface grinding

● OD grinding

● Centerless grinding

● Tool grinding

● Fine grinding

● Double disc grinding

● Slot grinding

| Name | 1A1 carbide sharpening resin bond diamond grinding wheel |

| Bond | Resin bond , Vitrified bond ,Metal bond , Electroplated |

| HS Code | 8202390000 |

| Products Range | Synthetic diamond powder /natural diamond powder Electroplated diamond grinding wheel /electroplated saw blade/ electroplated diamond disc Resin bond diamond grinding wheel/ resin bond saw blade/ Metal bond diamond grinding wheel/metal bond saw blade Vitrified bond diamond grinding wheel Diamond Microdermabrasion tips |

| Features | Stable quality Fast delivery Reasonable price OEM/ODM production |

| Logo | Acceptable, can be lettering according to the customers’ requirements. |

| Sample lead time | 3-7 days |

| Delivery time | 7-10 days. Large quantity please contact us to discuss |

| Usage | Mainly used for machining tungsten carbide, PCD, PCBN, ceramic, cermets, crystal tungsten, carbide |

Advantages of Resin Bond Grinding Wheels

- Extremely efficient - Resin bond wheels work quickly and effectively, making it fast and easy to finish any grinding task.

- High-performing - These wheels provide a free-cutting experience, offering corner retention and a higher depth of cut.

- Durability - Over time, the wear and heat resistance of resin bond wheels increase. They sharpen themselves, maintin low temperatures during operation, and are resistance to overloading, which helps prolong their lifetime value.

- Easy to dress - Equipped with the proper tool, you can quickly dress the wheel to angle, straight, or special radius forms.

- Multi-purpose - Our wheels can be formulated for both wet and dry grinding applications.

- If you need a grinding wheel that will last longer, improve your operations, and comes with dedicated support, look no further than Eagle Superabrasives.