Products

- Resin Bond Diamond Wheels (19)

- 1A1 Diamond Wheels (9)

- CBN Sharpening Wheel (18)

- Centerless Grinding Wheels (4)

- 1A1R Diamond Wheels (5)

- Electroplated Diamond Wheels (6)

- Electroplated Diamond Tools (6)

- Metal Bond Grinding Wheels (14)

- PCBN Tools (8)

- CNC Grinding Wheels (4)

- Vitrified Bond Wheels (7)

- Diamond Dressing Tools (7)

Contact Us

Tel:+86371-67129055 Mr Li: 15003895611

Fax:+86371-67129055

Email:shineabrasives@vip.163.com

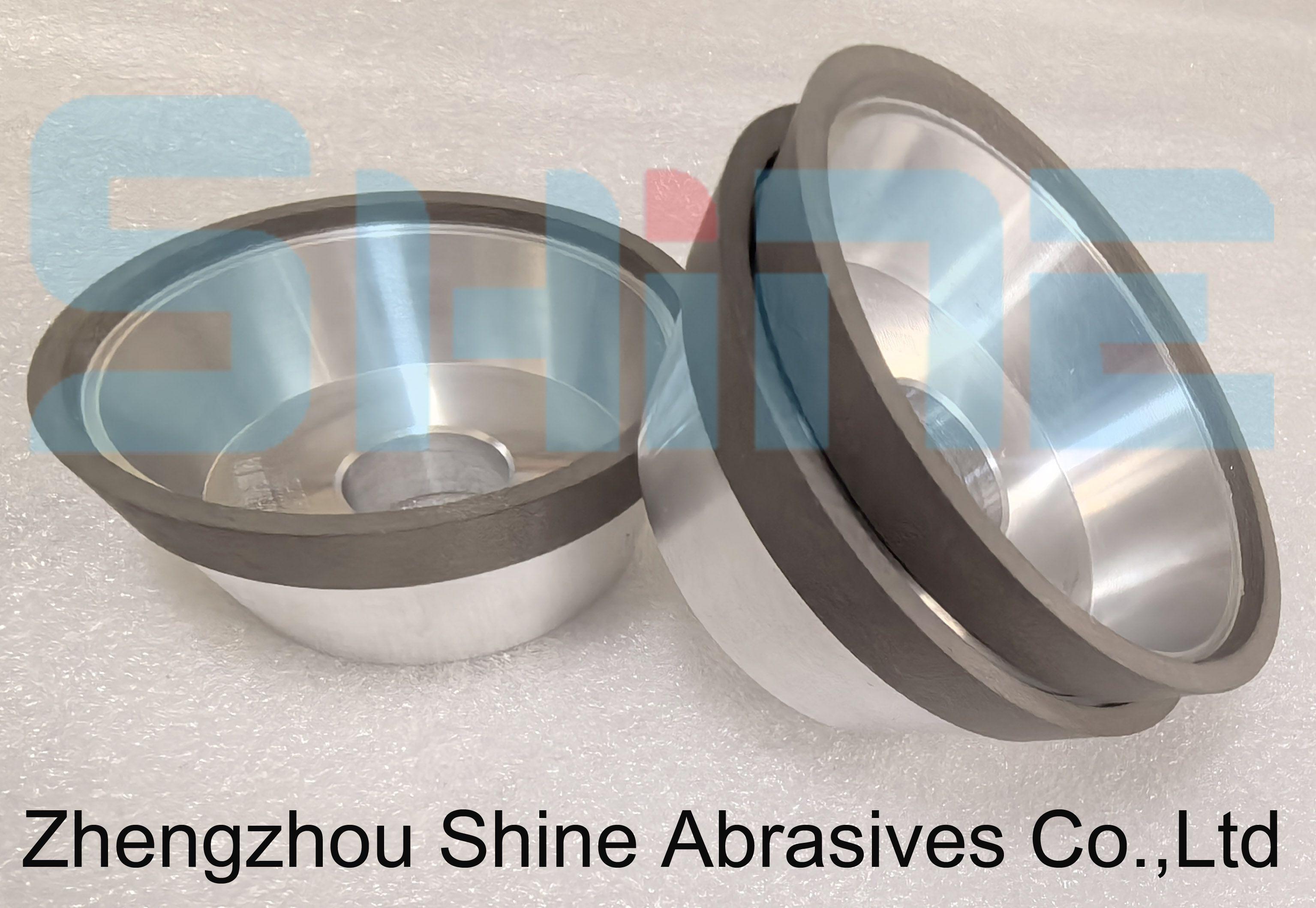

Resin Bond Diamond Wheels

Diamond GrindingWheel for Sharpening Metal Carbide

Resin bond diamond grinding wheel suits to grind carbide, hard steel, hard alloy, all kinds of serrated teeth, sharpen edges, milling cutter, Suitable for the surface grinding and outer circular grinding of cemented carbide measuring tools, tungsten steel, alloy steel.Also suit for grinding high-alumina porcelain, optical glass, agate gem, semiconductor material, stone, etc. We will provide a complete solution for tools manufacturing process, including fluting, gashing and clear edge, relief angle grinding .

| Product Name | Diamond Grinding Wheels |

Material |

Diamond + Aluminum Base |

Diameter |

100mm/Customized |

Grit |

40#-600#,Customized |

Advantage |

Longer Working Life,High Grinding Efficiency,High |

Service |

OEM ODM |

Model NO. |

1A1, 1V1, 6A2, 11V9, 12A2,Customized |

MOQ |

1 Piece |

Bond |

Resin Bonding |

Transport Package |

Cartons |

Production Capacity |

100000 PCS a Year |

Specification |

Diameter: 50mm-200mm |

1. High cutting efficiency, good self-sharpening, less blocking, reducing the grinding burn occurs when the phenomenon of work.

2. Good flexibility will help to improve the surface roughness, mainly used for rough grinding, semi-fine grinding, polishing and other processes.

3. Compared to conventional silicon carbide , resin diamond wheel has good material removal rates, longer wheel life and lower grinding costs.

4. Resin bond diamond wheels generally remove material up to 10 times faster than metal bond wheels